Window Restoration

WINDOW RESTORATION

Total restoration of existing sashes, frames, AND single pane glass

Restoration is recommended when there is significant decay of the wood elements, the glass is loose, or more than one third of the putty is loose or missing. When all other hardware, weather stripping, or pulley and rope problems are presumed present to a degree, they are corrected as part of the sequence of sash restoration.

SCOPE OF WORK

Nearly all parts reused and all new parts same as existing in material, profile, and proportion

Sash removed from building, catalog per opening

White corrugated plastic panels installed for light transmission and weather protection — every other window so as to not darken rooms completely

Plywood installed for security and weather protection

Jambs restored with sash removed

Windows scraped of all loose paint

Abatron Epoxy consolidant used where fibers are weak

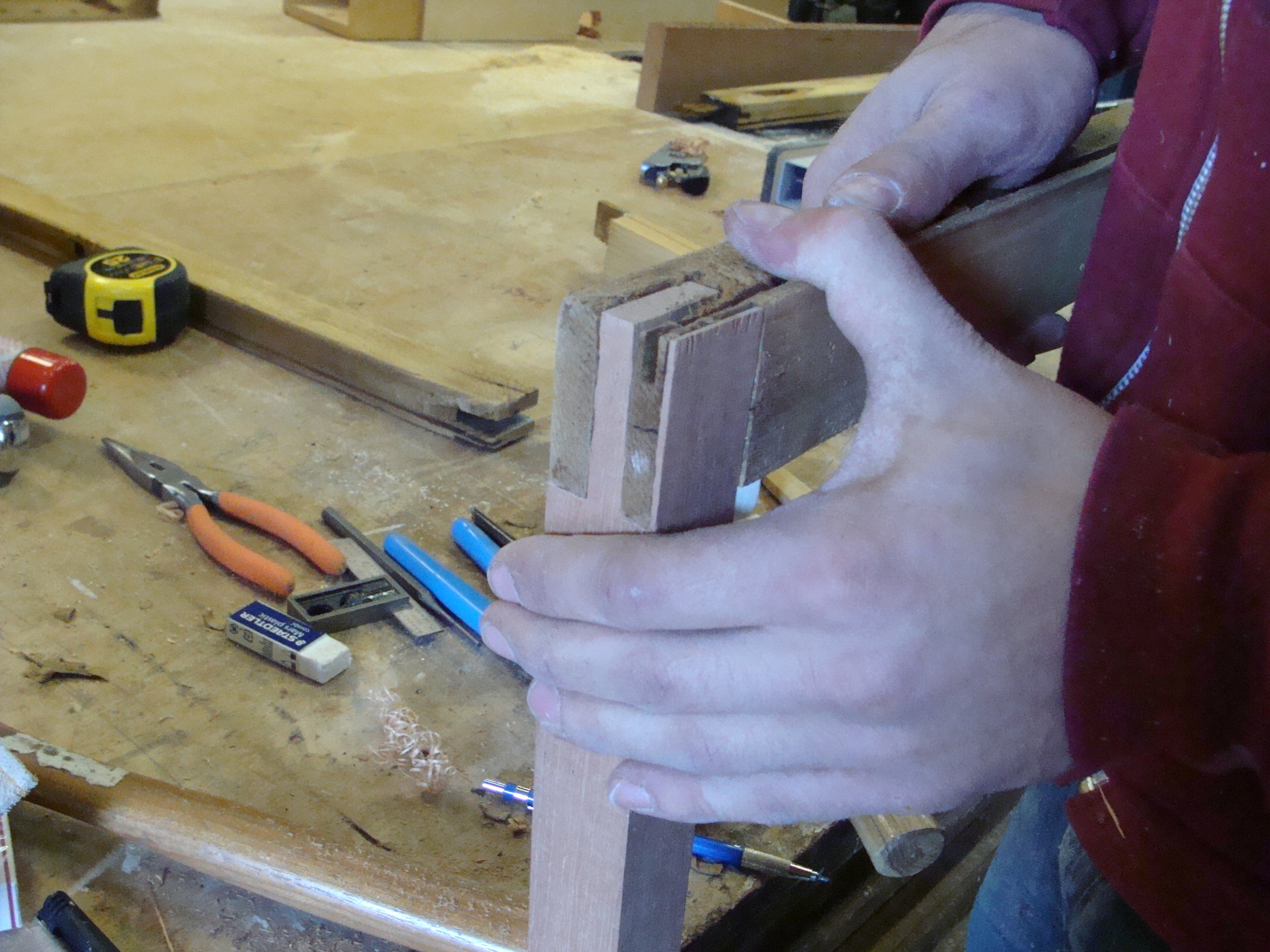

Real wood Dutchmen repairs where pieces are missing

Zinc interlocking weather-strip replaced with same for sound and lasting seal

Final sanding with Hepa filter vacuum attached

Period style zinc interlocking weather-strip retrofitted to operable sash for sound and lasting seal

Sash pulleys stripped of paint, wire brushed and lubed

Jambs primed before sash installation.

Sashes restored in shop

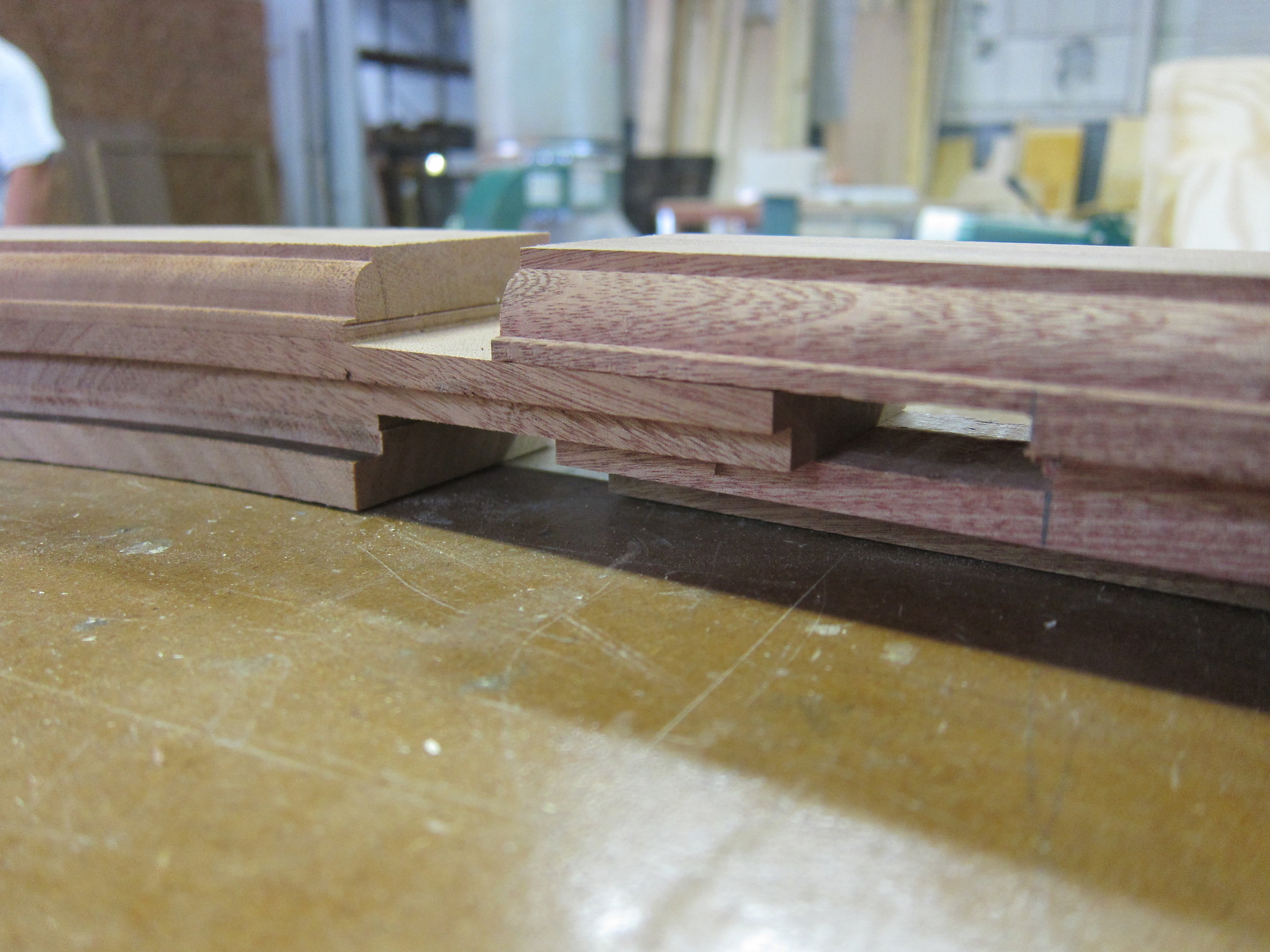

Each sash is steamed to soften old putty and release historic glass form sash

Each sash pressure chemically stripped, removing all loose paint, glazing putty and glass Epoxy consolidants and abatron resin fill used as necessary to secure loose fibers. Wood Dutchman and replacement parts fabricated as necessary

Remaining paint is chemically stripped at a specialty stripping shop

Epoxy consolidants and Abatron resin fill used as necessary to secure loose fibers. Wood Dutchman and replacement parts fabricated as necessary

Glass cleaned of paint and dirt, replaced if damaged

Historic glass reused whenever possible. Replacement glass to be in kind

Glass is bedded on modern silicone acrylic sealant

New, traditional linseed oil based glazing putty at all mullions

Sashes prime painted on all surfaces prior to installation

Sashes installed

All restored parts reused in installation

Sashes hung on new brass chain with new stop bead and parting bead to match existing

Top and bottom sash to operate with ease, latch with authority and seal well

PROCESS GALLERY

Click on an image to enlarge. Hover over image to learn more.